UN Bulk Bags for Dangerous Goods

UN bulk bags (FIBC) are specifically designed and made to store and transport dangerous and hazardous goods. United Nation has established directives for the safety of human and property and to prevent environment pollution. They have outlined specific criteria and standards for FIBC when it requires to store and transport dangerous goods.

Bulk Bags Australia can supply FIBC bulk bags for hazardous materials that comply UN standards by testing through independent reputed testing laboratory, usually LABORDATA in Germany.

UN certified bags have labelling and visual pictogram requirement for identification. Labelling depends on hazardous materials that will be filled in that specific bag. In Australia, appropriate labelling on FIBC bulk bags is required by the government and non-government authorities for transporting, storing and exporting of hazardous materials.

There are 8 classes of hazardous labels (pictograms) on UN bulk bags for dangerous goods as below.

UN Bag Hazard Signs

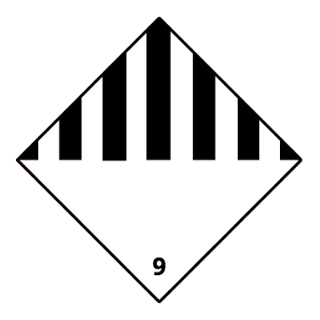

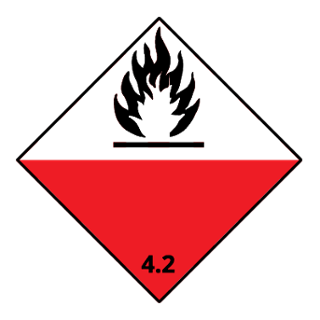

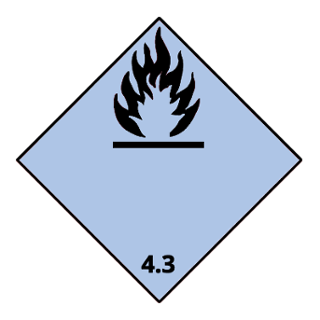

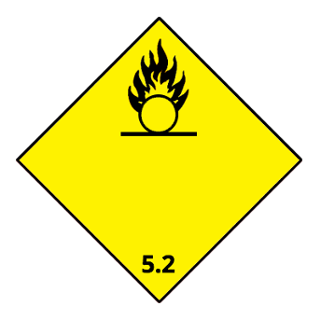

| Pictogram | Dangerous Goods Class |

|---|---|

|

Class 4.1: Flammable solids, self reactive substances and desensitized explosives. |

|

Class 4.2: Substances liable to spontaneous combustion. |

|

Class 4.3: Substances that emit flammable gases when they come in contact with water. |

|

Class 5.1: Substances that oxidize. |

|

Class 5.2: Organic peroxides. |

|

Class 6.1: Toxic substances. |

|

Class 8: Corrosive substances. |

|

Class 9: Miscellaneous dangerous substances and articles |

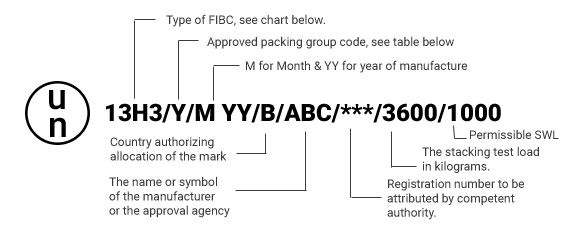

FIBC Bulk Bags Unique UN Number

UN bags have 3 levels of packing groups for dangerous goods transportation.

Degree of Danger - High, Medium, Low.

| Degree of Danger | Packing Group | UN Symbol | Max. Allowed Volume |

|---|---|---|---|

| High | I | X | 1.5 m3 |

| Medium | II | Y | 3.0 m3 |

| Low | III | Z | 3.0 m3 |

For high degree of danger (packing group I), UN Symbol X is not applicable to FIBCs, but only to rigid IBCs.

There are four types of FIBCs for dangerous goods made from woven polypropylene:

13H1: woven PP without coating and without liner

13H2: woven PP, coated and without liner

13H3: woven PP, uncoated and with liner

13H4: woven PP, coated and with liner

A UN FIBC is certified by carried out the following tests successfully:

Top lift test: The FIBC is loaded with six times of the rated load.

Drop test: The FIBC filled with the rated load is dropped in an upright position from a height of 80 cm or 120 cm.

Topple test: The FIBC filled with the rated load is toppled from a height of 80 cm or 120 cm.

Righting test: After being toppled, the FIBC filled with the maximum load is lifted to an upright position on one or two loops.

Tear test: A 100 mm tear is made on one of the sides of the FIBC filled with the maximum load. The FIBC is then filled with twice its maximum load for a minimum of five minutes. Finally, the FIBC is suspended with its SWL for five minutes.

Stacking test: The filled FIBC with 1.8 times of rated weight is stacked on top of another FIBC.

Industries where UN bags are used

Mining & MineralsChemicals

Pharmaceuticals